Contest Coordinator: Bruce Gregory

3-person teams will be given a detailed blueprint and steel material to make a completed project within a 3-hour time period. Some of the project parts are premade, the team will make parts too via OA cutting and mechanical cutting with angle grinder/cutoff wheel. Parts are assembled, tack welded and final welded via GMAW & SMAW weld processes (post-secondary includes GTAW DC- process). The individuals must know how to read and interpret blueprint drawings & weld symbols. Utilizing a tape measurer, square, protractor and skills in welding with GMAW (MIG) & SMAW (E7018, E6011) are crucial. GTAW (TIG) for post-secondary is needed as well. Skill in safely utilizing an angle grinder with grinding disc, cutoff disc, & sanding disc for metal finishing is also critical. Knowing how to drill holes in steel is important. Teamwork and time management is paramount to a successful team. Safe shop practice must be employed, at all times.

There will be a multiple-choice test for welding fabrication knowledge administered the evening prior to hands-on competition.

Click here for Tools and Equipment list.

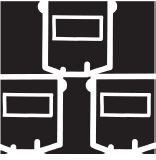

2024 Drawing/Blueprint of project. REVISED

Hints to a potential winning team:

The key to this contest is individual skill of the various welding, cutting, fabrication disciplines, team skills, and team management. The highest scoring teams have best team management that translates to TIME MANAGEMENT. Organization of assignment of skills to the various points and stages of project build is imperative. We do NOT expect all teams to finish or submit a completed project at conclusion of work time allotted. Those teams that are able to complete the project get the highest grade in Team Management/Cooperation category.

Fit & Finish of submitted project carries a higher-grade scoring category. AKA Quality of Finished Project